Introduction

The e-Learning Document is mainly

intended to cover TECHNICAL KNOWLEDGE of tools and services that are not

covered or partly covered in the Standard Work Instruction (SWI). It is not

Intended to cover Job Process “Design”, “Prepare”, “Execute” and “Close”. The

SWI is the standardized document for all job design, preparation, execution and

close procedures.

Objectives

By the end of the module the

trainee should be able to :

•Categorize

the different types of UPOs (Unintentional Pull Off)

•Recognize

the common causes of UPOs in Schlumberger Operation

•Identify

and Understand the HSE risks related to UPOs

•Identify

and Understand the Quality and Business consequences of UPOs for Schlumberger

and clients

•Recognize

the preventive and mitigation procedures and tools available

•Become

familiar with the relevant standards and

Standard Work related to UPOP (Unintentional Pull off Prevention)

In order to understand what is an unintentional Pull off lets review a general P.S. logging set up. Logging unit is located in an area that will allow for the required operation, then Basic Equipment which composed of: Sheave Hanger, Sheave wheels, Chain, Sling, and Pressure control equipment are rigged up and finally Logging Cable is feed through.

To assemble the required string a logging head is attached to the cable, this equipment acts as the mechanical and electrical connection between cable and tools, once head is installed the string can be connected and lowered into the well. Of this setup the Basic Rig up Equipment handles the force generated by the cable weight , tool weight and friction forces when string is in movement.

The force seen by the top sheave will be twice the current tension, while the tension seen at the lower sheave will be a function of the angle and current tension. For this reason the Safe working load for the equipment is higher than the specifications of the cable.

The wireline cable as our conveyance method will see the force generated by the cable weight , tool weight and friction force when the string is in movement; the Maximum strength will depend type the being used , you can find this on the tool planner in the cable properties tab, Safe Working Load is the value used as the maximum tension that a cable can be exposed to.

|

| Wireline Conveyance System |

What

is a UPO? Whenever

a weakpoint or cable is broken unintentionally

What

are the consequences of a UPO?

Client:

Loss production, revenue, Damage to

Equipment

Schlumberger:

Loss of revenue, reputation,

Loss /Damage to

Equipment

YOU:

Zero Tolerance….

Lihat Video Cable Structure dibawah ini:

TIME for

TENSION Buildup

§Example 1

–Tool

at 10,000 ft and

speed of 1000 ft/hr. With a stuck tool,

a 2500lbs increase in tension will take?

–18

feet of cable stretch and 1 minute.

§Example 2

–Tool

coming to surface at 1000 ft/hr with 150ft

of

cable from the truck to the lubricator.

When bumping up, a 2500lbs increase in tension (which is enough to risk

breaking a weak point) will take?

–3

1/3 inches of cable stretch and 1 second.

➤Pull Off Analysis

➤Pull Off – Cases for revision

➤TIME for TENSION Buildup

➤Pull

Off PREVENTION

–WP

Calculations

–WP

Selection

–Prevention

Tools

–Surface

Checks

–Winch

Operator’s notes

➤Operations

–Speed

Limits

–RIH,

POOH

➤Case

Study and Scenarios

Weak Point Selection Premises

1.

Make

sure you can pull off without breaking the cable (Respect the cable SWL)

•

2.

Choose

the largest Weakpoint suitable for the job

Weakpoints

§Rigid Modular Weakpoint

§Flexible Weakpoint

§Spider Weakpoint

§ECRD

TABLE-Rigid

Modular Weakpoints

Rigid

Weakpoints are identified with color code and

written rating.

Don’t trust the color

coding system when installing or checking a weakpoint,

always look for the rating that

is stamped on it.

TABLE- Flexible Weakpoint

➤Solid (Rigid) weakpoints

are more susceptible to damage to

high

shock,

as in

perforating jobs, than flexible weakpoints.

Spider Weakpoint (CH)

➤Technique

sensitive!

➤The impact strength of a spider weakpoint decreases as the number of inner

armours decrease.

➤When a spider rope socket make up

torque is increased beyond the

recommended value, it will cause the impact

strength to decrease.

§Solid weakpoints experience a ~ 4% strength

reduction per 100 DegF increase

from

room temperature (75 DegF).

The effect is not cumulative,

that is, the

weakpoint recover its full strength when returned to room temperature.

1.Make

sure you can pull off without breaking

the cable (Respect the cable

SWL).

2.Choose

the largest Weakpoint suitable for the job.

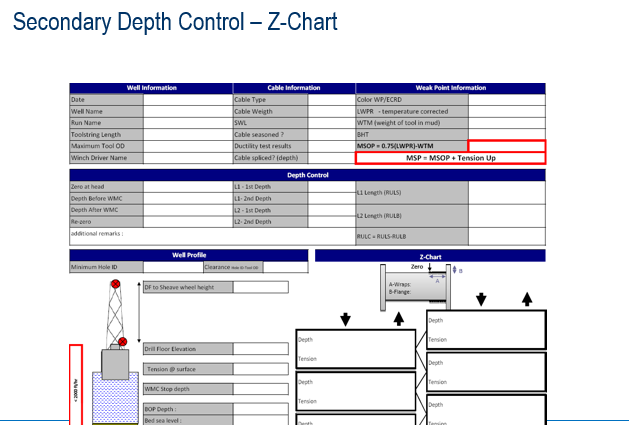

Upper WP rating (temp corrected) < 1/2 cable strength Ŧ - cable weight (in mud)

Ŧ

SWL =

50% of Cable Ends Fixed Break Strength

Max. Safe Pull = Normal Tension - Wt. of Tool in Fluid + .75

(Lower WP Rating)

➤Max

Pull by FE without Consulting District Manager:

–75%

of Lower Weakpoint

Rating

–50%

of Ends Fixed Break Strength

➤Know

Your Normal Logging Tension

➤Consider

effects of DRAG

•Temperature

Effects

•Buoyancy

Effects

Maximum Safe OverPull

MSOP is constant

throughout

the jobŦ

Ŧ Only if temperature remains fixed

Communication

➤Hand Signals

➤Intercom (UKI)

➤Radios

(to be continued)

Comments